Computer-Assisted Gripper and Fixture Customization

via Rapid Prototyping

5.2 Gripper stroke and approach clearance

Another important design constraint is the gripper stroke limit. Common pneumatic grippers typically have a very restrictive stroke length. Our previous examples have suggested that our approach presumes complete enclosure of a grasped object, though use of such designs can require an excessive actuator stroke. For practical use, we must guarantee that our gripper fingers not only achieve form (or frictional form) closure, but we must also assure that objects to be grasped can be approached without interference in the gripper-open position.

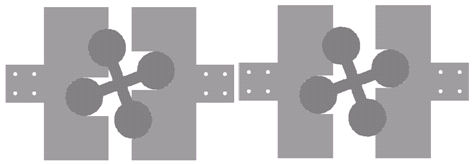

A variant on our design approach is illustrated in Figure 5, in which only part of the component's contour is used to define the shape of narrower fingers. The length of each finger layer is therefore another design variable to be considered.

Figure 5 shows the feasibility of using fingers that do not fully surround a grasped object. This planar example, however, oversimplifies the problem by giving the misleading impression that an arbitrarily small gripper stroke can be used, since the part can be approached from above. With reference to the part and gripper-design of Figure 3, it is clear that the approach-clearance problem is not so lightly dismissed. In this realistic example, a collision-free horizontal approach would require excessive finger stroke (exceeding the maximum diameter of the head). A collision-free vertical approach requires less finger stroke, but is more difficult to analyze. To compute approachability, we propose the following algorithm. For each proposed finger layer, the computed left and right boundaries are shifted outwards (computationally) by a distance equal to the width of the finger stroke (minus some pragmatic tolerance).

Next, compute the 2-D projection of the part to be grasped, superimposing slices normal to the gripper-approach direction. The range of heights of part slices included in this superposition should be from the top (maximum) to the height at which the finger-layer under consideration is intended to contact the part during grasp. (Part profiles below this elevation would not interfere with the gripper's approach). If the boundary of this computed part projection is bounded by the shifted gripper-finger contours, then it is assured that this finger layer can approach the part from above within the available actuator stroke without interference. In continuing research, we are automating this test, as well as using results from 2-D part projections to help alter finger profiles to assure clearance. Note that the selection of slice height influences the clearance for a gripper layer at that height. Thus, the number and location of gripper slice planes is another important parameter in the design space.