Computer-Assisted Gripper and Fixture Customization

via Rapid Prototyping

5.3 Multipurpose grippers

The examples given so far have illustrated the design process for single-purpose fingers (and, by analogy, fixtures). Ideally though, the fingers should be capable of manipulating multiple objects, hence reducing the need for multiple grippers. This would in turn decrease the number of tool-change operations needed for a given assembly operation, thereby reducing cycle times. (Similar objectives are being pursued by Brost and Peters using modular fixtures [23].)

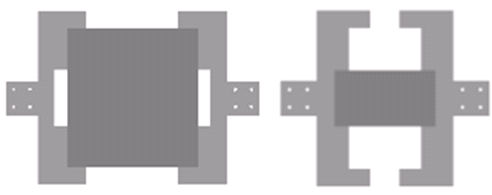

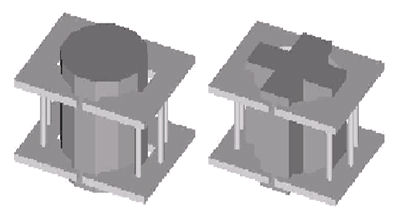

Figure 6 shows how a single pair of gripper fingers can be used to manipulate multiple objects. Multipurpose gripper designs can be generated by first computing the geometric superposition of the objects to be handled, then subtracting the result from the finger blanks. The resultant finger designs would have surfaces that conform to the left and right halves of the superposition envelope.

While this algorithm is feasible, it does not guarantee a correct solution. For example, it would not work for concentric spheres of varying radii, since the resultant finger designs would only be capable of grasping the largest sphere. In such cases, it would be necessary to search for alternative solutions. This can be done by rotating and/or translating one or more of the parts considered, then repeating the algorithm.

In addition, the aforementioned approach presumes that the objects are all grasped using the same jaw separation. While pneumatic grippers typically are restricted to short strokes, servoed parallel-jaw gripper designs typically enable longer strokes. Assuming such a long-stroke gripper motivates consideration of additional gripper-finger shapes corresponding to grasp of multiple objects at different jaw separations.

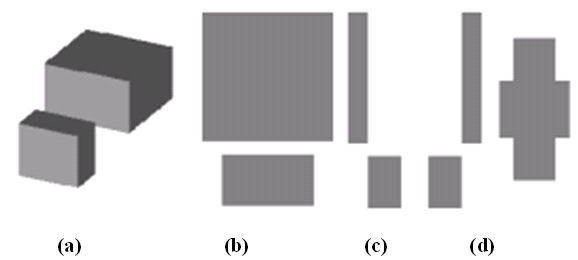

An algorithm for generating multipurpose designs has also been developed, one which allows the user to specify different jaw separations for each part. This approach requires extracting sections (or �divisions�) from the left and right sides of each part, as shown in Figure 7. From these sections, a hypothetical �composite part� is generated, comprising both the geometric union of all the left divisions and the union of all the right divisions. Gripper fingers that would grasp this hypothetical object are then generated, and subsequent testing is performed to verify that these fingers would likewise hold each of the original objects. This technique allows different jaw separations to be used for each part, as illustrated in Figure 8. As a result, it also allows the fingers to hold objects of different sizes, even when the smaller parts can be fully enclosed by the larger ones.