Computer-Assisted Gripper and Fixture Customization

via Rapid Prototyping

5.1 Compensating for concavities

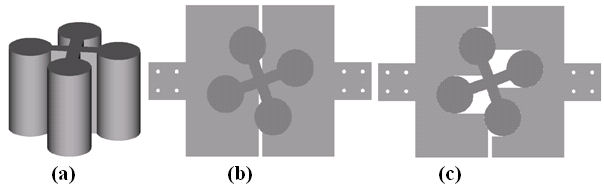

A complication with our basic approach is illustrated by the example of Fig 6. Figure 6b shows a naive application of our approach, resulting in gripper fingers which cannot be opened to release the part (shown in black). In such circumstances, the finger contours must be modified to allow horizontal accessibility. A robust algorithm for generating horizontally accessible contours has been developed and implemented, the results of which are shown in Figure 4.

The solution can be conceptualized as the result of using the actual part as an electrode of a ram-EDM machine, where the electrode is advanced into the gripper finger block in the direction of the intended finger stroke, eroding a cavity into the finger block conforming to the shape of the part. In this conceptualization, the resulting tool surface is not concave; however, the surface is describable as a single-valued function with respect to the independent variable along an axis parallel to the parting-line between fingertips. We can define corresponding upper and lower envelopes of part outlines with respect to finger stroke directions, from which we can define gripper-fingers that are feasible for part grasp and release. The chosen direction of finger stroke is a free parameter in the search space for gripper designs.